Table of Contents

ToggleIntroduction

Gas turbines are among the most powerful and efficient mechanical devices ever created. They are widely used in industries such as power generation, aviation, oil and gas, and naval propulsion. In India, gas turbines play a key role in peaking power plants, combined-cycle systems, and backup generation units. This blog dives deep into how gas turbines work, explores their different types, and highlights the world’s most advanced and powerful gas turbine technologies in 2025.

What is a Gas Turbine?

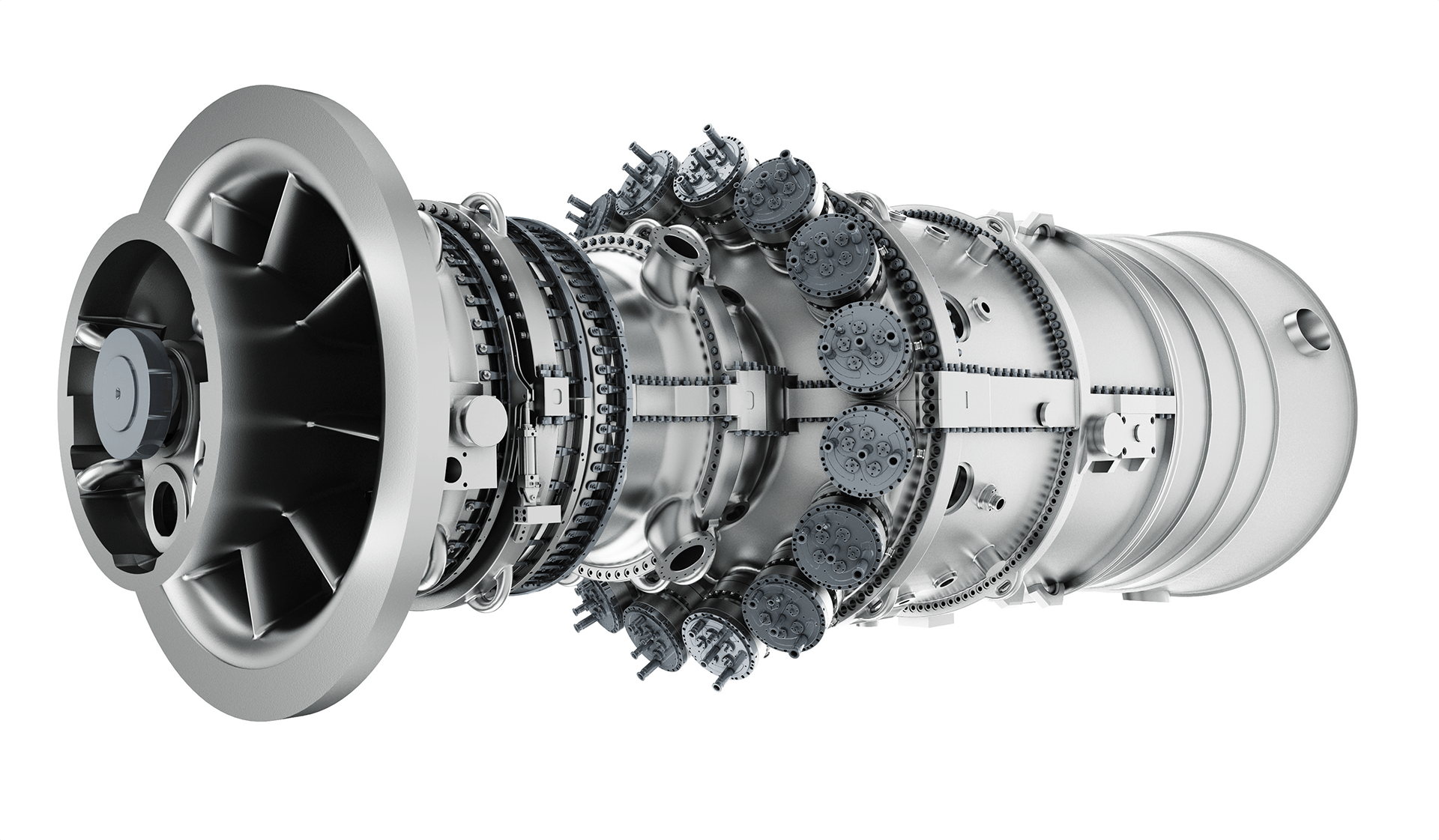

A gas turbine is a heat engine that converts chemical energy from fuel into mechanical energy using a continuous combustion process. The resulting energy is used to drive electrical generators or produce thrust in aircraft engines. Gas turbines operate based on the Brayton Cycle, involving three main steps: compression, combustion, and expansion.

Detailed Working of a Gas Turbine (Brayton Cycle)

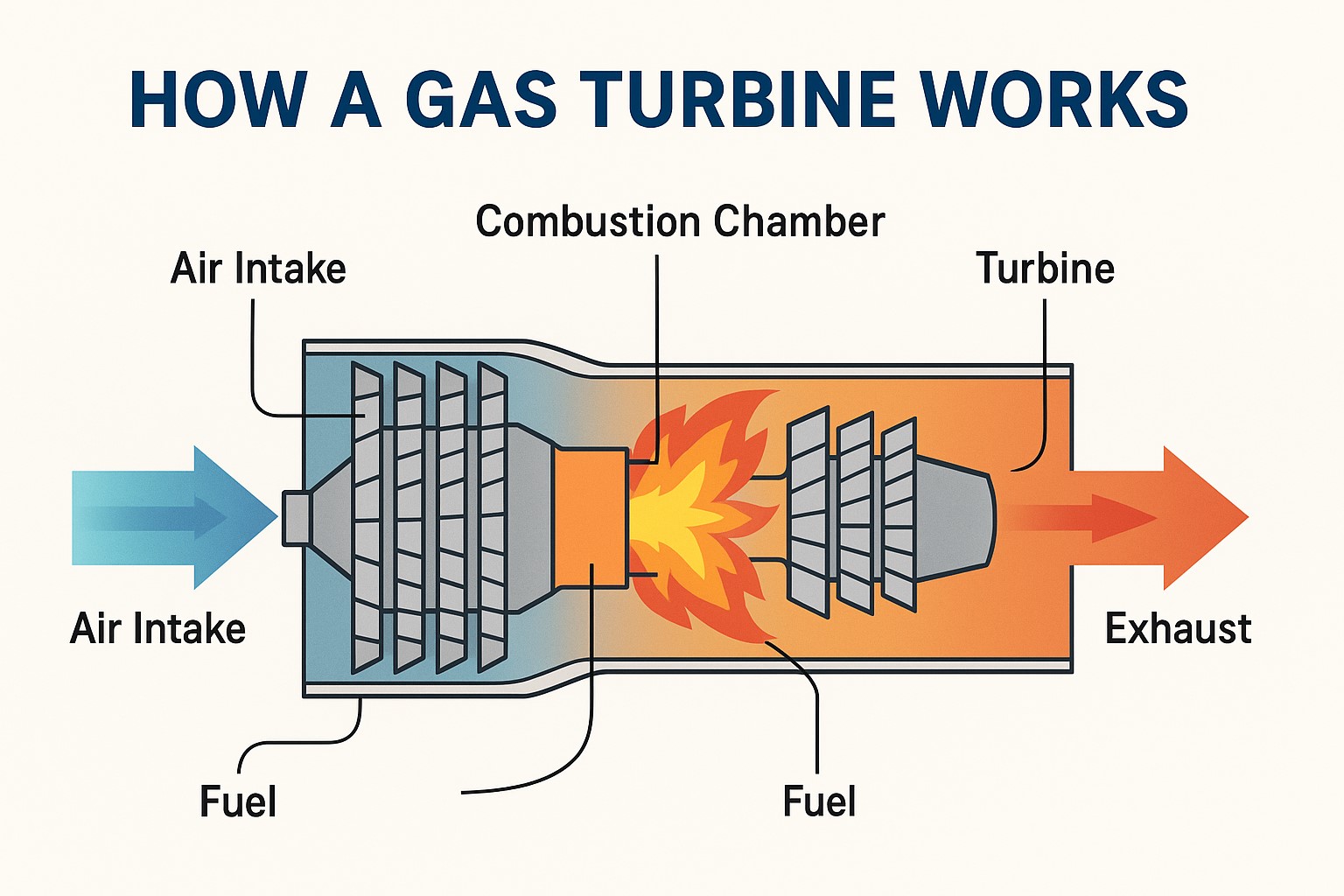

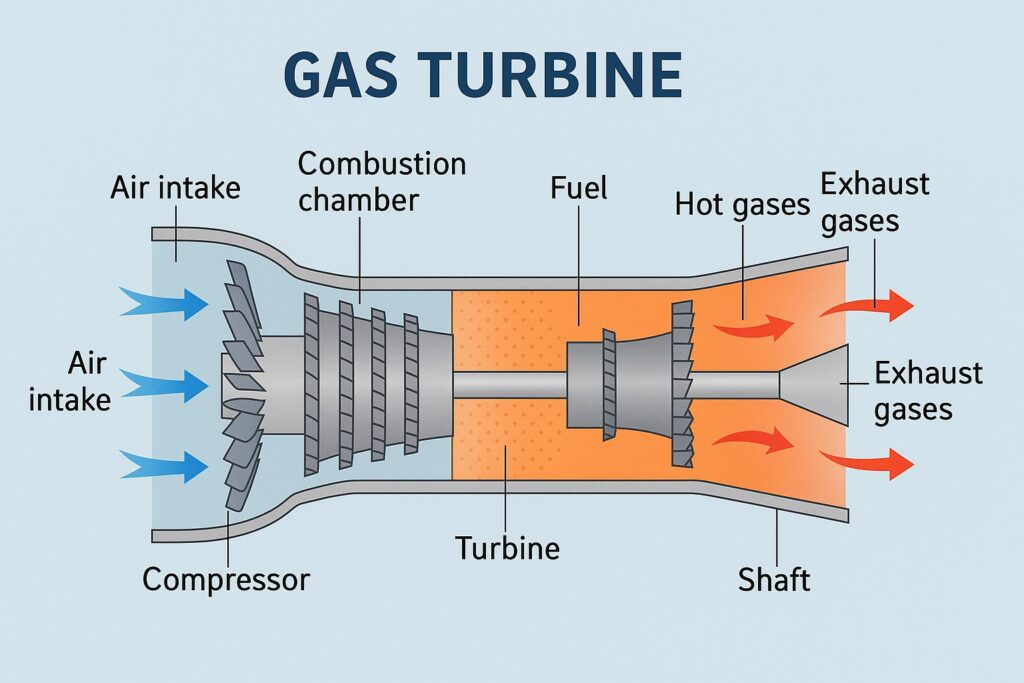

1. Air Intake

Ambient air is drawn into the turbine through a large air intake system, which filters out dust and debris. A smooth airflow is crucial to minimize pressure losses and ensure efficient turbine operation.

2. Compression

The filtered air enters a multi-stage axial or centrifugal compressor. This device compresses the air to high pressure, often 10 to 30 times atmospheric pressure. This step increases the air’s temperature and pressure, creating ideal conditions for combustion.

3. Combustion

In the combustion chamber, the high-pressure air is mixed with fuel, typically natural gas or aviation-grade kerosene. This mixture is ignited, resulting in a high-temperature (up to 1,500°C), high-pressure gas flow.

4. Expansion (Turbine Stage)

The hot gases expand through several stages of turbine blades, causing them to spin. This rotation powers both the air compressor at the front of the system and any connected equipment, such as an electric generator or aircraft propeller.

5. Exhaust and Power Output

he spent gases exit the turbine via the exhaust system. In open-cycle systems, this energy is lost. In combined-cycle systems, the exhaust heat is captured to produce steam, which drives a steam turbine for additional power generation.

Main Components of a Gas Turbine

- Air Intake: Draws in ambient air

- Compressor: Increases air pressure

- Combustion Chamber: Burns the fuel-air mixture

- Turbine: Extracts energy from expanding gases

- Exhaust: Releases spent gases

- Generator (optional): Converts mechanical to electrical energy

1.Aero-Derivative Turbines: Based on jet engine designs, these are lightweight, fast-starting, and ideal for mobile or backup applications.

2.Heavy-Duty Industrial Turbines: Large, durable turbines used in power stations. They are designed to run for extended periods.

3.Open Cycle Gas Turbines (OCGT): Operate without using exhaust heat. These are used for peaking power during high demand.

4.Combined Cycle Gas Turbines (CCGT): Utilize exhaust heat to run a steam turbine, achieving efficiencies up to 65%.

Gas Turbines in India

India uses gas turbines in states like Gujarat, Maharashtra, Kerala, and Andhra Pradesh. Though efficient and clean, their use is limited due to the high cost of natural gas. Most gas turbine projects are located near LNG terminals or gas fields.

Notable Indian Projects:

NTPC Kawas, Gujarat: Combined cycle plant

GAIL Anta, Rajasthan: Uses GE Frame 9

BHEL Kochi: 360 MW LNG-based power plant

Top Gas Turbine Manufacturers

- GE (General Electric): GE 9HA.02, LM6000

- Siemens Energy: SGT-800, SGT6-8000H

- Mitsubishi Power: M701JAC

- Rolls-Royce: Trent 60

- BHEL (India): Partnered with global OEMs

World’s Most Powerful Gas Turbines (2025)

GE 9HA.02

- Output: 640 MW (single cycle)

- Combined cycle efficiency: 64%

- Used in France, Malaysia, and Japan

Mitsubishi M701JAC

- Output: 574 MW

- Advanced cooling and low emissions

Rolls-Royce Trent 60

- Output: 64 MW

- Fast start-up; ideal for naval and airport use

Gas Turbines vs Other Power Sources

| Feature | Gas Turbine | Steam (Coal) | Solar + Battery |

|---|---|---|---|

| Startup Time | Minutes | Hours | Instant |

| Pollution | Low | High | None |

| Cost per kWh | Moderate | Low | High (with storage) |

| Efficiency | 40–65% | 30–40% | 25–35% |

| Land Requirement | Compact | High | Varies |

Maintenance and Lifecycle

Gas turbines typically operate for 20,000–30,000 hours before requiring major maintenance. Common procedures include:

- Blade inspection and cleaning

- Shaft alignment

- Fuel system checks

- Combustor maintenance

Conclusion

Gas turbines remain vital in the global energy and aviation sectors due to their efficiency, power density, and flexibility. In India, while natural gas limitations have restricted their growth, newer technologies, hybrid fuels, and LNG infrastructure development may soon make gas turbines a more mainstream choice. For anyone in energy, engineering, or power management, understanding how gas turbines work is essential for the future of clean and reliable power.

What is the working cycle of a gas turbine?

as turbines operate on the Brayton Cycle, which includes three main steps: compression of air, combustion of air-fuel mixture, and expansion of hot gases through turbine blades.

What is the name of the cycle of a gas turbine engine?

The working cycle of a gas turbine engine is called the Brayton Cycle.

Is a gas turbine better than a steam turbine?

Yes, especially in applications needing quick start-up and flexibility.

Can gas turbines run on hydrogen?

Yes, many modern designs support hydrogen blends, making them future-ready.