Table of Contents

Toggle☀️ Introduction To Monocrystalline and Polycrystalline Solar Panels

Solar energy is rapidly transforming India’s power landscape. Whether you’re planning a rooftop installation or an off-grid system, choosing the right type of solar panel is the first step.

Two main contenders dominate the market — Monocrystalline and Polycrystalline Solar Panels.

While both harness sunlight to produce electricity, they differ in efficiency, design, manufacturing, and cost.

In this detailed guide, we’ll compare Monocrystalline vs Polycrystalline Solar Panels across all major factors — helping you decide which one is the best investment for your home or business.

🔋 What Are Monocrystalline Solar Panels?

Monocrystalline Solar Panels, often called Mono panels, are made from a single continuous crystal structure of pure silicon.

These panels have a uniform black color and rounded cell edges, giving them a premium look.

🔧 How They’re Made

Made using the Czochralski process — a single silicon crystal is grown into a large cylindrical ingot.

This ingot is sliced into thin wafers and assembled into solar cells.

Because of the pure crystal structure, electrons flow more freely, resulting in higher efficiency.

✅ Key Features

Color: Deep black

Shape: Rounded cell corners

Material Purity: High

Typical Efficiency: 18% to 23%

Performance in Low Light: Excellent

Temperature Tolerance: Better at high temperatures

🔷 What Are Polycrystalline Solar Panels?

Polycrystalline Solar Panels, or Poly panels, are made from multiple silicon crystals melted together.

They have a bluish hue with a distinctive mosaic-like texture.

🔧 How They’re Made

Manufactured by melting several fragments of silicon together to form a block.

The block is cut into square wafers — this process is faster and cheaper but results in less crystal uniformity.

Electron movement is slightly hindered by grain boundaries, leading to lower efficiency compared to monocrystalline panels.

✅ Key Features

Color: Blue (reflective texture)

Shape: Square cell edges

Material Purity: Moderate

Typical Efficiency: 15% to 18%

Performance in Low Light: Average

Temperature Tolerance: Slightly lower

Monocrystalline vs Polycrystalline Solar Panels – Comparison Table

| Feature | Monocrystalline Panels | Polycrystalline Panels |

|---|---|---|

| Material | Single-crystal silicon | Multi-crystal silicon |

| Color | Black | Blue |

| Efficiency | 18–23% | 15–18% |

| Space Efficiency | High | Moderate |

| Performance in Heat | Better | Slightly lower |

| Cost (₹/Watt) | ₹28–₹38 | ₹24–₹32 |

| Lifespan | 25+ years | 20–25 years |

| Recycling Impact | Complex (due to doping materials) | Easier |

| Ideal For | Limited rooftop space | Large rooftops or budget projects |

🌞 Efficiency: The Biggest Difference Monocrystalline vs Polycrystalline Solar Panels

When comparing Monocrystalline vs Polycrystalline Solar Panels, efficiency is the top deciding factor.

Monocrystalline panels have higher conversion efficiency (up to 23%), meaning they generate more power from the same sunlight area.

💡 Real-World Example:

If you have a 3 kW rooftop system,

Monocrystalline panels might require around 13 panels (each 450W).

Polycrystalline panels might need 15–16 panels (each 400W) for the same power output.

👉 Thus, if space is limited, Monocrystalline is the smarter choice.

💰 Monocrystalline vs Polycrystalline solar panel price

When it comes to initial investment, Polycrystalline panels are more affordable.

They have a simpler manufacturing process, resulting in lower per-watt pricing.

However, Monocrystalline panels can offer better long-term returns through:

Higher efficiency (fewer panels needed)

Better durability

Lower degradation over time

Verdict:Monocrystalline vs Polycrystalline Solar Panels,

If you want the best ROI and long lifespan — go Monocrystalline.

If your budget is tight — go Polycrystalline.

🌡️ Temperature Performance: Handling Indian Heat

India’s climate brings intense sunlight and high ambient temperatures.

Monocrystalline panels perform slightly better under heat due to a lower temperature coefficient (about −0.3% per °C).

This means they lose less efficiency as temperatures rise.

For example, if both panels operate at 45°C:

Monocrystalline might lose only 2–3% efficiency.

Polycrystalline could lose 4–5%.

🏠 Aesthetic Difference – Looks Matter Too!

If rooftop aesthetics matter to you, Monocrystalline panels look more elegant with their uniform black color.

They blend better with modern rooftops and are often used in premium installations.

Polycrystalline panels, with their blue glittery pattern, appear more industrial and noticeable from a distance.

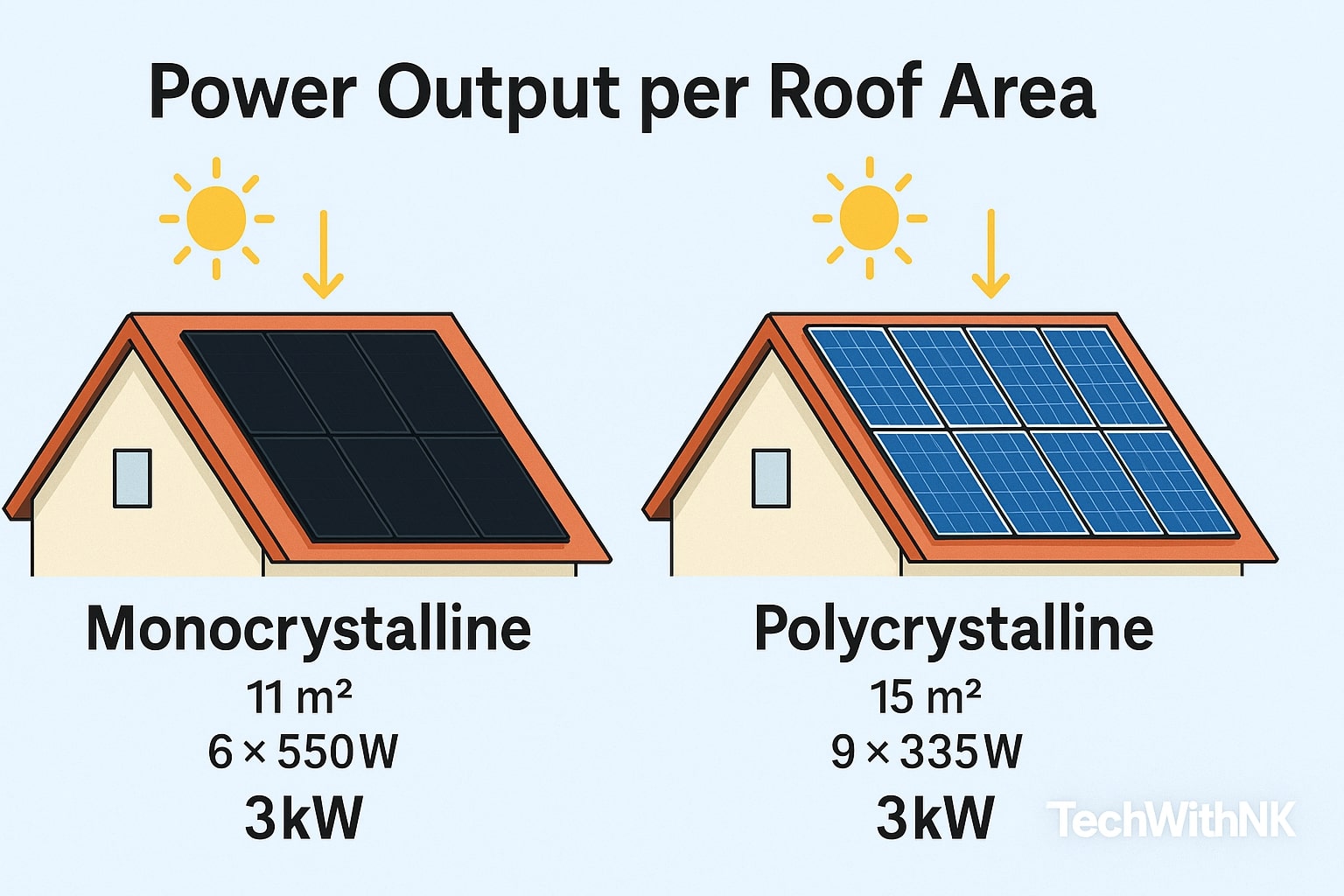

🧩 Space Requirement

Because of their higher efficiency, Monocrystalline panels generate more power per square meter.

So, for small rooftops, they’re the better choice.

Example:

A 5kW system with Monocrystalline panels may need ~22 panels.

The same system using Polycrystalline may need ~26–28 panels.

♻️ Environmental Impact

Polycrystalline panels use waste silicon fragments, making them more eco-friendly during production.

Monocrystalline panels, on the other hand, waste some silicon during the ingot slicing process.

However, both are non-toxic, recyclable, and safe for the environment during operation.

🔌 Availability in India (2025)

Most leading brands in India now produce both types:

| Brand | Monocrystalline | Polycrystalline |

|---|---|---|

| Tata Power Solar | ✅ | ✅ |

| Waaree | ✅ | ✅ |

| Adani Solar | ✅ | ✅ |

| Loom Solar | ✅ | ✅ |

| Vikram Solar | ✅ | ✅ |

| RenewSys | ✅ | ✅ |

Monocrystalline panels (especially PERC and TOPCon types) are now the default choice for most 2025 installations due to price reduction and higher power output.

⚙️ Technological Variants (2025 Update)

Mono PERC (Passivated Emitter Rear Cell): Improved light capture and higher yield.

Bifacial Monocrystalline Panels: Generate power from both sides (front and back reflection).

Half-Cut Cell Design: Increases efficiency and reduces shading losses.

Polycrystalline technology is gradually being replaced by these advanced monocrystalline variants.

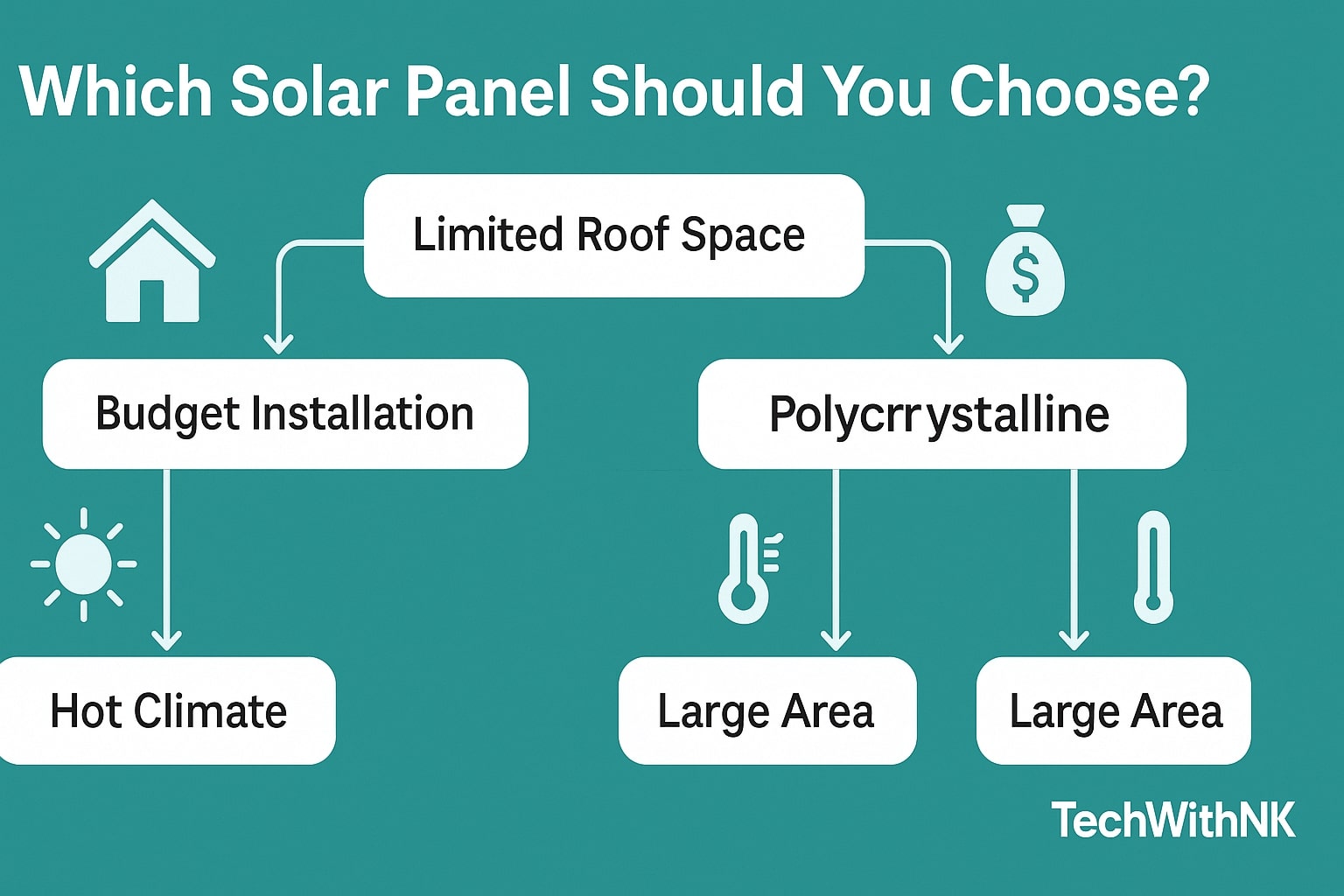

📈 Which Solar Panel Type Should You Choose?

Monocrystalline vs Polycrystalline Solar Panels

| Your Situation | Recommended Type |

|---|---|

| Small rooftop | Monocrystalline |

| Large rooftop with budget constraints | Polycrystalline |

| High electricity consumption | Monocrystalline (PERC) |

| Off-grid or rural setup | Polycrystalline |

| Premium aesthetic installation | Monocrystalline |

💡 Expert Verdict (TechWithNK Opinion) For Monocrystalline vs Polycrystalline Solar Panels

After comparing Monocrystalline vs Polycrystalline Solar Panels, it’s clear that Monocrystalline panels offer:

Higher efficiency

Better performance in heat

Longer lifespan

More aesthetic design

While Polycrystalline panels remain affordable, the price gap has narrowed significantly in 2025, making Monocrystalline panels the preferred option for most Indian homes.

✅ TechWithNK Recommendation:

Choose Monocrystalline PERC panels (450W or above) from trusted brands like Tata Power, Adani, or Waaree for best results and reliability.

🏁 Final Thoughts For Monocrystalline vs Polycrystalline Solar Panels

The debate of Monocrystalline vs Polycrystalline Solar Panels has evolved.

Once known for being expensive, Monocrystalline panels have now become affordable and far more efficient — making them the clear winner for most homeowners in 2025.

If you’re planning to install solar for your home, office, or farm, go for Mono PERC panels (450W–550W) with 25-year performance warranty.

They ensure maximum savings, cleaner energy, and reliable performance for decades.

Monocrystalline vs Polycrystalline Solar Panels Which is better for Indian climate?

Monocrystalline panels handle heat and low-light conditions better — ideal for India’s tropical weather.

monocrystalline vs polycrystalline solar panels efficiency

When comparing Monocrystalline vs Polycrystalline Solar Panels, efficiency is the top deciding factor.

Monocrystalline panels have higher conversion efficiency (up to 23%), meaning they generate more power from the same sunlight area.

Are Polycrystalline panels outdated?

Not exactly — they’re still used for budget and large-area projects, but Monocrystalline is now dominant.