Table of Contents

ToggleIntroduction – The Age of Electrification at Sea

For more than a century, the ocean has been ruled by the roar of diesel engines and gas turbines. From massive cargo carriers to stealthy submarines, fossil fuel-based propulsion has powered global trade and defense. But now, the maritime world is entering a silent revolution — one driven not by noise and smoke, but by clean electricity.

Electric ships are emerging as the future of marine transportation. They promise higher efficiency, reduced emissions, and lower operational costs. In the age of climate commitments and decarbonization, the International Maritime Organization (IMO) has set ambitious goals — cutting greenhouse gas emissions by 50% by 2050 compared to 2008 levels. This goal is reshaping how ships are designed, powered, and operated.

Today, shipbuilders and navies are investing heavily in Integrated Full Electric Propulsion (IFEP), hybrid systems, and advanced battery storage. Industry leaders like Rolls-Royce, ABB, Siemens, and GE Marine are pioneering this shift. Even India is joining the race with indigenous programs aimed at developing electric and hybrid naval vessels.

Electric propulsion isn’t just about environmental responsibility — it’s also about strategic and operational superiority. Silent electric drives mean stealthier submarines and more efficient ships with flexible power distribution. Let’s dive deep into the technology that’s redefining the seas.

Basics of Marine Propulsion

What Is Marine Propulsion?

Marine propulsion refers to the system that moves a ship through water. Traditionally, this involves converting fuel energy into mechanical energy that spins a propeller or waterjet.

The core components are:

Prime Mover: The main power source (diesel engine, gas turbine, or electric motor).

Transmission System: Shafts, couplings, and gearboxes transferring power.

Propulsor: Propeller, pod, or jet that generates thrust.

Major Types of Marine Propulsion

Diesel Propulsion: Most common in commercial ships; uses large 2-stroke or 4-stroke engines.

Gas Turbine Propulsion: High-power, lightweight option for naval vessels (e.g., Rolls-Royce MT30).

Steam Turbine Propulsion: Used in older ships and nuclear submarines.

Hybrid Propulsion: Combines engines with electric motors for flexible operation.

Full Electric Propulsion (FEP): Turbines or generators produce electricity that powers propulsion motors directly — no mechanical linkage.

A ship’s propulsion design depends on mission type: cargo ships focus on efficiency, while naval vessels prioritize speed, stealth, and agility.

Conventional Marine Propulsion Systems

Before the electric era, ships were powered almost entirely by mechanical drives:

Diesel Engines

Large marine diesel engines burn heavy fuel oil to produce torque.

Power transmitted through reduction gears and shafts to propellers.

Advantages: mature technology, high energy density of diesel fuel.

Drawbacks: high emissions (SOx, NOx, CO₂), vibrations, and maintenance costs.

Gas Turbine Engines

Use air compression and fuel combustion to spin a turbine shaft.

Much lighter and faster response than diesel engines.

Used in warships like destroyers and frigates (e.g., Indian Navy’s INS Vikrant uses MT30).

Limitation: lower fuel efficiency at partial loads.

Nuclear Propulsion

Used mainly in submarines and aircraft carriers.

A nuclear reactor heats steam turbines which drive generators or shafts.

Extremely long range, but expensive and complex.

Challenges of Traditional Systems

Mechanical coupling means inefficiency at partial loads.

Bulky gearboxes and shafts take space.

High maintenance and fuel logistics burden.

Difficult to integrate renewable or stored electric power.

These limitations paved the way for hybrid and electric propulsion systems.

The Rise of Electric Propulsion

What Is Electric Propulsion?

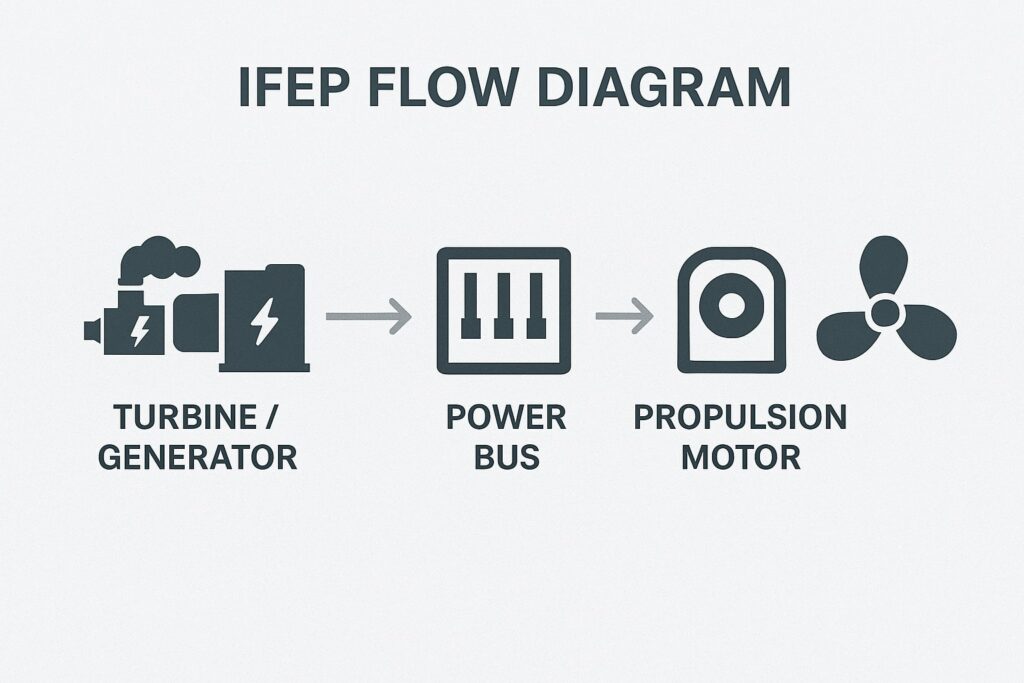

Electric propulsion replaces mechanical transmission with electrical power flow. Turbines or diesel generators produce electricity, which is distributed through a Power Bus to propulsion motors and ship systems.

This concept, known as Integrated Full Electric Propulsion (IFEP), is a game-changer. It turns the entire ship into one big power grid — distributing energy flexibly where needed.

Working Principle

Turbine / Diesel Generator → Power Bus → Propulsion Motor → Propeller

↓

Ship Systems

Instead of directly driving propellers, the engines only generate electricity. Motors then convert that electric energy back to mechanical thrust.

Advantages of IFEP

🔇 Silent Operation: Ideal for submarines and stealth ships.

⚙️ Flexible Power Use: Same power source runs propulsion and onboard electronics.

💰 Fuel Efficiency: Engines run at optimal RPM regardless of ship speed.

🧩 Modular Design: Easier maintenance and redundancy.

🌱 Low Emissions: Compatible with renewable or battery input.

Real-World Example

The Royal Navy’s Type 45 Destroyers and US Navy’s Zumwalt-class destroyers both use IFEP systems, with Rolls-Royce and GE supplying gas turbines and generators.

Hybrid-Electric Ships

Hybrid systems blend the best of both worlds — mechanical engines and electric motors.

How Hybrid Ships Work

Low-Speed Mode: Uses electric motors powered by batteries or generators.

High-Speed Mode: Switches to direct engine drive or turbine power.

Regeneration: Some systems recover energy during deceleration or downhill (for ferries).

Types of Hybrid Configurations

Parallel Hybrid: Engine and motor both connected to propeller shaft.

Series Hybrid: Engine powers a generator, which drives electric motors.

Plug-in Hybrid: Batteries can be charged from shore power.

Notable Hybrid Ships

MS Roald Amundsen: World’s first hybrid electric cruise ship (Hurtigruten).

Zumwalt-Class Destroyer (U.S.): Gas turbines + electric drive for silent cruising.

INS Vikrant (India): Features Rolls-Royce MT30 gas turbine with electric systems.

Benefits

Reduced fuel consumption (up to 20–30%).

Lower noise and vibration.

Backup power flexibility during system faults.

Battery and Energy Storage Technologies

As in electric cars, batteries are the heart of electric ships. But maritime batteries must withstand vibration, humidity, and extreme load cycles.

Major Battery Technologies

| Type | Energy Density | Lifespan | Safety | Example Use |

|---|---|---|---|---|

| Li-ion (LFP, NMC) | High | 5–10 years | Good | Ferries, yachts |

| Solid-State | Very high | 10+ years | Excellent | Future systems |

| Flow Batteries (Vanadium) | Moderate | Long cycle | Very safe | Grid-scale storage |

| Supercapacitors | Low | Infinite cycles | Very safe | Peak power smoothing |

Challenges

Weight and space: marine batteries are massive.

Charging infrastructure at ports.

Fire safety and cooling systems (thermal runaway prevention).

Emerging Solutions

Battery swapping for short-range ferries.

Hybrid energy storage (battery + supercapacitor).

Smart battery management with AI load balancing.

Power Electronics & Propulsion Motors

The core of electric propulsion lies in motors and converters that deliver smooth, silent power.

Common Marine Motors

Induction Motor (IM): Rugged, cost-effective; used in large drives.

Permanent Magnet Synchronous Motor (PMSM): High efficiency and torque density.

Switched Reluctance Motor (SRM): Simple design, robust, minimal maintenance.

Azipod Drive (by ABB): A motor directly integrated into a rotating pod beneath the ship — provides 360° thrust.

Power Electronics

VFDs (Variable Frequency Drives) regulate motor speed.

DC Bus Systems distribute power across propulsion and hotel loads.

Converters/Inverters enable hybrid integration with batteries or fuel cells.

ABB’s Azipod Propulsion

Reduces fuel use by up to 15%.

Increases maneuverability — no rudder needed.

Installed on cruise liners and icebreakers globally.

Major Players in Marine Electrification

⚙️ Rolls-Royce Marine Power Systems

Developer of the MT30 Gas Turbine, the world’s most power-dense marine turbine (36–40 MW).

Used in UK’s Queen Elizabeth-class carriers and India’s INS Vikrant.

Works with IFEP architecture for flexible energy management.

⚡ ABB Marine

Pioneered Azipod propulsion.

Offers full hybrid and zero-emission ferry systems.

Leading supplier for cruise and Arctic vessels.

🔋 Siemens Energy

Offers SISHIP EcoProp and BlueDrive PlusC systems.

Modular approach integrating batteries, motors, and automation.

🌍 GE Marine

Supplies propulsion control systems for naval destroyers.

Collaborates with Rolls-Royce for integrated power generation.

India’s Role in Electric Warships

India is emerging as a regional leader in naval electrification.

Current Developments

INS Vikrant (IAC-1): Powered by four GE LM2500+ turbines and advanced electric systems.

Future Project 18 Destroyers: Expected to adopt IFEP systems for stealth and efficiency.

Cochin Shipyard, GRSE, and Mazagon Dock are developing hybrid propulsion systems domestically.

DRDO and BHEL are working on indigenous energy storage and electric drive modules.

Partnerships

Rolls-Royce India collaborating on MT30 integration and training programs.

L&T involved in hybrid sub-systems and automation controls.

Strategic Significance

Reduces dependence on imported fuel and components.

Boosts Make in India and Atmanirbhar Bharat initiatives.

Environmental and Strategic Impact

Electric propulsion isn’t just cleaner — it’s smarter.

Environmental Benefits

Up to 90% reduction in CO₂ and NOₓ emissions.

Zero fuel leakage and marine pollution.

Enables hybrid renewable integration (wind or solar-assisted systems).

Strategic Benefits for Navies

Quieter operation → stealth advantage for submarines and destroyers.

Reduced thermal signature → harder to detect.

Lower maintenance → higher uptime in combat missions.

Commercial Benefits

Reduced operating costs over lifetime.

Compliance with IMO 2030 & 2050 carbon goals.

Competitive advantage for shipping lines adopting green technology.

Future Innovations in Marine Propulsion

Hydrogen Fuel Cells:

Produces electricity from hydrogen and oxygen, emitting only water vapor.

Ideal for zero-emission ferries and coastal ships.

Example: MF Hydra (Norwegian hydrogen ferry).

Ammonia and Methanol Fuels:

Can be used in dual-fuel engines with zero-carbon potential.

Wind-Assisted Electric Ships:

Retractable sails or rotors supplement battery power.

AI-Powered Energy Management:

Smart algorithms optimize power flow and predict maintenance.

Autonomous Electric Vessels:

Drones of the sea — unmanned ships navigating using sensors and AI.

Example: Yara Birkeland (Norway’s autonomous electric container ship).

Challenges Ahead

Battery Weight: High energy density still insufficient for long-haul ships.

Charging Infrastructure: Limited port electrification.

Initial Cost: Hybrid and IFEP systems are capital-intensive.

Safety: Battery fire suppression and marine certification standards.

However, these challenges are rapidly being addressed with new chemistries and digital control systems.

The Road Ahead – The Future of Naval and Commercial Vessels

The future fleet will be a blend of:

Hybrid-electric cargo ships powered by fuel cells.

Fully electric ferries and passenger boats for short routes.

Silent, AI-controlled naval destroyers and submarines.

By 2035, electric propulsion could dominate new ship designs, driven by environmental laws, energy economics, and defense strategy.

India, with its Make in India drive and shipbuilding capability, stands ready to lead the Asian region in electric marine technology.

Conclusion – The Silent Revolution

The shift to electric propulsion represents one of the biggest transformations in maritime history since the steam engine.

From the deep rumble of diesel to the quiet hum of electric motors, the sea is turning green — literally and figuratively.

Electric ships promise:

Cleaner oceans 🌊

Quieter operations 🔇

Smarter power management ⚡

Stronger national capabilities 🇮🇳

As technology advances, we’ll see fleets of intelligent, connected, and sustainable ships — the true flagbearers of a blue and green revolution at sea.